Introduction Aluminum collapsible tubes are widely used in cosmetic, pharmaceutical, and adhesive packaging, but many buyers still confuse them with aluminum pipes. This in-depth guide from Junsam Packaging explains the essential differences between aluminum collapsible tubes and aluminum pipes—from structure, purpose, and materials to production methods and applications. Learn how to choose the ideal aluminum product for your needs, avoid common purchasing mistakes, and ensure compatibility with cosmetic filling lines. Unlike rigid industrial aluminum pipes, aluminum collapsible tubes are soft, hygienic, and printable, making them the ideal solution for creams, ointments, and adhesives. We’ll also explore sustainability advantages and professional tips for choosing the correct diameter, shoulder type, and coating. […]

In the fast-evolving beauty and personal care industry, packaging plays a crucial role in both product protection and customer experience. Among the many cosmetic packaging solutions available today, laminated tubes (ABL tube) stand out as one of the most versatile, durable, and visually appealing options. Whether for eye cream packaging, skincare serums, pharmaceutical ointments, or toothpaste, laminated tubes are redefining how brands balance functionality with design. This article will walk you through everything you need to know about ABL laminated tubes—their structure, benefits, applications, customization options, and answers to frequently asked questions. If you are searching for a reliable laminated tube manufacturer or supplier, this guide will help you make the […]

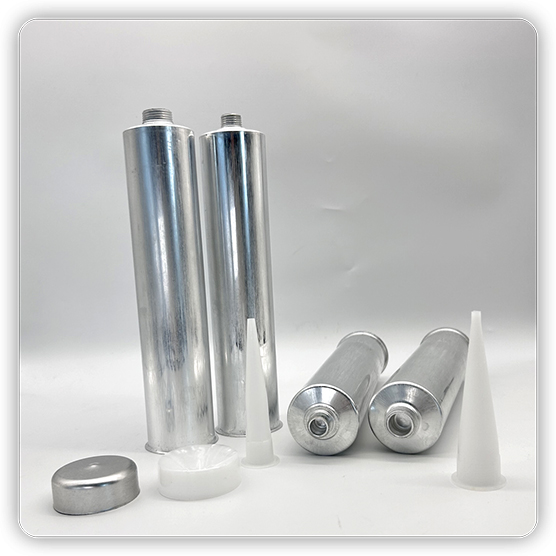

What Are Aluminum Cartridge Tubes? The cartridge tubes are rigid, cylindrical containers designed to hold and dispense high-viscosity materials (often under pressure) such as various sealants and adhesives. Unlike soft, collapsible tubes, rigid aluminum cartridge tubes do not collapse due to their thick and rigid walls. Main Components of a Rigid Aluminum Cartridge Tube 1. Tube Body Cylindrical, seamless, or minimal seams. Formed by impact extrusion. Wall thickness ~0.3 – 0.5 mm for rigidity. Often lacquered inside for chemical resistance. Printed or lacquered outside for branding. 2. Bottom Closure Usually one of these designs: Separate piston (plunger) Many cartridges have a plastic piston inserted at the bottom: Moves upward as the […]

Aluminum Tube Packaging Reshapes the Adhesive Industry. Aluminum glue tubes have evolved beyond their basic packaging functions to become symbols of technical excellence and environmental responsibility. With innovations such as internal coating technologies, smart tube caps, and advanced nano-printing, aluminum packaging is not merely a packaging upgrade—it is a strategic move to support ESG initiatives and appeal to the sustainable values of consumers, particularly the environmentally conscious Gen Z. Why Are Global Glue Brands Upgrading to Aluminum Tube Packaging? Revealing the 5 Core Advantages In adhesive packaging, aluminum tubes increasingly replace traditional plastic and glass bottles. Global brands such as 3M and Henkel are transitioning to aluminum tubes as their preferred […]

Through material innovation and structural optimization, aluminum cartridges have completely solved the problem of silicone clogging at extreme temperatures, becoming the core carrier of high-precision gluing in the era of Industry 4.0. Their temperature resistance, corrosion resistance, and intelligent monitoring functions can significantly improve the production yield and equipment utilization rate in the automotive, electronics, medical, and other industries. Enterprises should combine their process requirements and choose regular suppliers with customization capabilities and technical support to maximize the return on investment. Eliminate silicone clogging! Aluminum cartridges ensure smooth workflow at extreme temperatures. In high-precision fields such as industrial manufacturing and automotive electronics, silicone materials’ sealing and gluing processes require extremely […]

The evolution of leak-proof technology in pigment packaging—from threaded seals to modern advanced sealing systems—has revolutionized the aluminum tube for pigment. This innovation ensures near-zero leakage and aligns with environmental protection and market adaptability trends. As consumer preferences shift toward improved functionality and sustainability, these advanced aluminum tubes set the stage for a new era of artistic innovation and zero waste. 1. The Rise of Aluminum Tube for Pigment in the Industry In an industry where quality and durability are paramount, the aluminum tube for pigment has become the container of choice. Aluminum tubes offer unmatched watercolor and oil paint benefits compared to plastic or laminated alternatives. Their inherent properties […]

Aluminum caulking tubes solve the anti-leakage, corrosion resistance, and environmental protection needs of silicone sealant packaging through material science innovation and precision manufacturing processes. With the global emphasis on lightweight and recyclable materials, aluminum tubes will continue to dominate in construction, automobiles, and medical care. In the future, the industry needs to further optimize its carbon footprint, develop innovative packaging solutions, and consolidate its technological moat as the gold standard. 1. Core technical advantages of aluminum caulking tubes 1. Unparalleled sealing and corrosion resistance Aluminum caulking tubes are made of aluminum ingots with a purity of 99.7%. A dense protective layer is formed through an internal spraying process, and double sealing […]

Glue aluminum tube packaging has become the gold standard in the adhesive industry with its irreplaceable sealing, environmental protection, and customization capabilities. Enterprises need to choose suitable tube structures (such as single-layer aluminum tubes or two-color plastic-wrapped aluminum tubes) according to product characteristics and pay attention to the compliance and technological innovation of the supply chain. With the advancement of green manufacturing and clever packaging, aluminum tube packaging will continue leading the industry’s upgrade. Glue aluminum tube packaging: the perfect solution for sealing and performance In the adhesive industry, packaging sealing and durability are directly related to product quality and user experience. In recent years, aluminum tubes have become the […]

Aluminum packaging for cosmetics: Technological breakthrough and commercial game under the sustainable wave Introduction: The green revolution behind the metallic texture In the global cosmetics market moving towards carbon neutrality, aluminum tube packaging has become the core choice of luxury brands such as Chanel and Estee Lauder with its environmental advantages of a 75% recycling rate and 95% reduction in renewable energy consumption. However, the environmental cost and supply chain pressure of bauxite mining have also made this material controversial. This article combines industry data, technical cases, and market trends to reveal the profound logic and future path of aluminum tube packaging. Environmental Advantages: Aluminum Packaging’s Sustainability- A Double-edged Sword […]

Empty aluminum tubes are at the forefront of sustainable beauty solutions. Henkel’s transition to recycled aluminum tubes for its hair coloration brands sets a new industry standard, benefiting both consumers and the environment. As the demand for eco-friendly products rises, aluminum’s recyclability and durability make it an ideal packaging choice for the future. Henkel’s Commitment to Sustainable Empty Aluminum Tubes As the beauty industry moves toward eco-friendly solutions, empty aluminum tubes have become a key player in sustainable packaging. Henkel, a global leader in consumer goods, has transitioned its major hair coloration brands to recycled aluminum tubes, reinforcing its commitment to reducing environmental impact. Driving Innovation in Eco-Friendly Packaging Henkel’s shift […]