What Are Aluminum Cartridge Tubes?

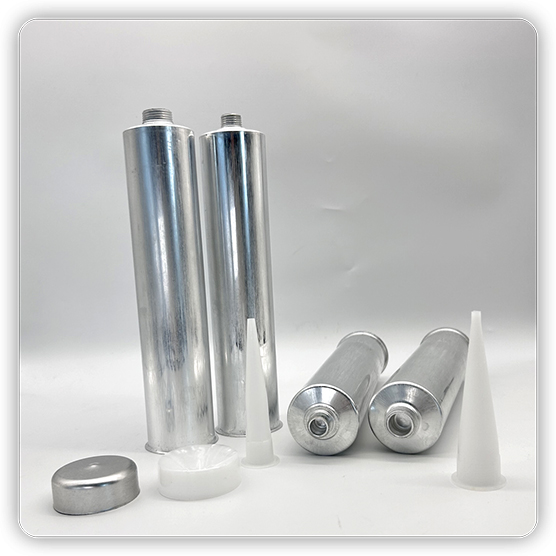

The cartridge tubes are rigid, cylindrical containers designed to hold and dispense high-viscosity materials (often under pressure) such as various sealants and adhesives.

Unlike soft, collapsible tubes, rigid aluminum cartridge tubes do not collapse due to their thick and rigid walls.

Main Components of a Rigid Aluminum Cartridge Tube

1. Tube Body

- Cylindrical, seamless, or minimal seams.

- Formed by impact extrusion.

- Wall thickness ~0.3 – 0.5 mm for rigidity.

- Often lacquered inside for chemical resistance.

- Printed or lacquered outside for branding.

2. Bottom Closure

Usually one of these designs:

Separate piston (plunger)

Many cartridges have a plastic piston inserted at the bottom:

Moves upward as the product is dispensed.

Helps push viscous material out cleanly.

Common in cartridges for high-viscosity sealants and adhesives.

3. Top Opening / Neck

Threaded or smooth, depending on closure type.

Designed to accept:

Threaded caps

Nozzles

Valve systems

4. Closure Components

EOE Caps (Easy-Open Ends)

Stands for Easy-Open End.

Type of metal cap commonly used for aluminum cartridge tubes (especially industrial sealants).

Features:

Aluminum or tinplate disc with a scored ring and pull-tab.

Allows the user to peel away the seal completely before fitting the nozzle.

Creates a hermetic seal during storage.

Prednosti:

Airtight and secure for moisture-sensitive products.

Tamper-evident.

Easy removal in the field without special tools.

Plastic Screw Caps

Alternative to EOE caps.

Often used if the product is not extremely moisture-sensitive.

May have an integrated piercer to open an aluminum foil seal.

5. Nozzle (Spout or Tip)

Often sold separately or supplied in the box.

Screws onto the cartridge neck.

Comes in various:

Lengths

Diameters

Shapes (straight, angled, wide bead)

Allows controlled application of material.

6. Foil Seal (Optional)

Some cartridges have a thin aluminum or plastic membrane heat-sealed to the neck.

Removed or pierced before use.

Prevents leakage and preserves product freshness.

7. Piston / Plunger (Optional) of cartridge tubes

Not all rigid cartridges have pistons.

Found mostly in cartridge tubes intended for high-precision dispensing.

Helps push product evenly without air gaps.

Key Characteristics of Aluminum Cartridge Tubes

1. Material Benefits:

- Excellent barrier properties protect the contents from oxygen, moisture, UV radiation, and contamination.

- Internal lacquer coatings prevent reaction between aluminum and aggressive chemicals.

- The cartridge tubes’ robustness withstands high dispensing pressures.

- 100% recyclable and more sustainable than plastic.

2. Construction & Design:

- The cartridge tubes are typically seamless or with minimal seams (made by impact extrusion).

- Standard volumes: 150 ml, 280 ml, 300 ml, 310 ml, 400 ml, etc.

- Often fitted with a plastic or aluminum piston (plunger) at the base to allow uniform extrusion. A threaded or nozzle-fitting neck for dispensing tips.

- Printing options: Offset printing for high-end branding. Lacquers in various colors for differentiation.

3. Advantages Over Plastic Cartridges

- Higher pressure resistance (important for very viscous or reactive materials).

- No moisture permeability—critical for products like polyurethane or MS polymers that cure with humidity.

- Superior chemical stability for aggressive chemicals.

- More premium appearance and perception in high-end markets.

4. Applications of Cartridge Tubes

- Construction adhesives and sealants (e.g. silicones, polyurethanes)

- Adhesives (MS polymer, epoxy)

- Bitumen sealants

- Greases, lubricants, and industrial pastes

- Specialized chemical products

- High-performance industrial adhesives

- Automotive chemical products

- Fire-resistant or specialty sealants requiring high stability

Environmental Aspect

- Aluminum rigid cartridges are recyclable and often preferred in sustainability-driven industries.

- ·Though costlier than plastic, they help companies meet eco-friendly packaging goals.

Frequently Asked Questions about Cartridge Tubes:

1. What are aluminum cartridge tubes used for?

Aluminum cartridge tubes are used to package and dispense high-viscosity materials like adhesives, sealants (e.g. silicone, polyurethane), lubricants, and other industrial or construction chemicals that require high-pressure application.

2. What are the main advantages of aluminum cartridge tubes over plastic ones?

Aluminum cartridges offer superior pressure resistance, excellent barrier properties against moisture and oxygen, higher chemical stability, and a more premium appearance. They are also 100% recyclable, making them more eco-friendly.

3. Do aluminum cartridges come with nozzles?

The nozzle (or spout) is typically supplied separately or included in the box. It screws onto the cartridge neck and is available in various shapes and sizes, allowing for the controlled application of the material.

4. How are aluminum cartridges sealed?

They may be sealed with EOE caps (Easy-Open Ends) or plastic screw caps. Some also feature an internal foil seal for added freshness and leak prevention. EOE caps are airtight, tamper-evident, and ideal for moisture-sensitive products.

5. What are the typical sizes available for aluminum cartridge tubes?

Standard volumes include 150 ml, 280 ml, 300 ml, 310 ml, and 400 ml, depending on the application. These sizes support various industrial and construction needs.

6. Are aluminum cartridge tubes environmentally friendly?

Yes. Aluminum tubes are fully recyclable and often chosen by companies aiming to reduce plastic waste and meet sustainability goals, even though they may be more expensive than plastic alternatives.